Apex International is proud to announce its global participation and sponsorship of the 4th Annual Women of Flexo Conference, taking place March 17–18 at the Watt Family Innovation Center at Clemson University in South Carolina. This year’s theme, “Unwind & Rewind,” brings together women from across the flexographic community to strengthen technical expertise, leadership skills, and industry connections.

Read More >Apex, LCP, and Stahl Partner on Real-World Coating Demo Project

Apex International, Lake County Press, and Stahl Collaborate on Print Demonstration Project Showcasing Real-World Coating Performance

Donora, Pennsylvania - Apex International has partnered with Lake County Press and Stahl on a collaborative print initiative designed to demonstrate real-world coating performance under true production conditions.

Read More >Apex goes live & in-person at FTA’s INFOFLEX Fall Conference

FRISCO, Texas — Celebrating 20 years in North America, Apex International welcomes all INFOFLEX Fall Conference attendees to visit Booth 207 for news about Apex’s expanding anilox product innovations. From October 4-5, 2021, Apex staff will be present at the Embassy Suites Convention Center in Frisco, Texas.

INFOFLEX at Fall Conference is a fully-expanded exhibit experience and part of FTA’s #FallConference2021 — the first live conference and exhibition for the entire flexographic industry in two years.

Read More >FlexoKITE Launches 2021 Problem-Solving Webinar Series

Flexo Print Quality Challenges Top the List of 2021 How-to Webinars

HAPERT, the Netherlands — FlexoKITE, a collaboration of leading flexo industry manufacturers, eagerly announces a series of technical problem-solving webinars in 2021, beginning with a February 3 deep-dive into White Ink Opacity Challenges. FlexoKITE’s mission is to empower its global webinar audience to examine and solve real-world print problems converters are facing today. FlexoKITE’s mission is the promotion of flexo methods that reduce product waste and press downtime.

Apex International Launches FlexoKITE in the Netherlands and India

Leading Flexo Technology Suppliers Convene for Knowledge-Sharing and Live-Demo Collaboration

HAPERT, the Netherlands — Delivering a “New, Better Normal” to flexo users seeking insight into workflow mastery and print perfection is the mission of five industry leaders who’ve created FlexoKITE, an Experience Center where end-to-end product and procedural harmony is made practical. Packaging suppliers, brands, and retailers gain instant access to best practices in the full flexo print process via in-person demos and live webinars. Apex launched FlexoKITE with its partners to demonstrate state-of-the-art equipment at work — in real-time — from Experience Centers in the Netherlands and India. FlexoKITE runs a fully-equipped integrated workflow of the latest-version equipment from Apex International (anilox), BOBST (inline flexo press), DuPont (plate), ESKO (prepress), and MacDermid (plate).

“Knowledge, Innovation, Technology, and Exploration” (KITE) are the driving forces that unify these companies to deliver real-world technical content not limited to a single product area. FlexoKITE provides print converters and brands a comprehensive view of the entire plate-to-print process, focusing on the finished printed product. An optimum printed product is achieved through synchronizing the plate-imaging, plate-processing, anilox, and press — all under one roof, presented step-by-step, and delivered to your computer screen, or in-real-life as health regulations permit.

What is FlexoKITE?

Apex appoints Phill Rogers as Market Area Sales Manager

Apex International is the leading manufacturer of anilox and metering roll solutions in the world. With 5 production facilities on 4 continents, a strong portfolio of clients in over 80 countries and a high-performance continuous improvement culture, Apex’s value proposition is founded on developing solutions to satisfy the complex print challenges our customers face every day. Apex products are used in the Flexographic printing industry as well as the Offset, Industrial Coating and the Corrugated industries. As of November 1st, Phill Rogers has been appointed as the Market Area Sales Manager in Ireland and the UK.

Read More >Apex International Exhibiting Latest Label & Flexo Offerings at Fall Conference

DONORA, PA – Apex International, the globally leading manufacturer of anilox and metering solutions and exclusive distributor for Bellissima DMS, Hamillroad’s award-winning screening technology, is exhibiting at FTA’s 2019 Fall Conference in Charlotte on October 28-29.

Read More >Apex appoints Carl Brock as Global Application Specialist

Apex International is the leading manufacturer of anilox and metering roll solutions in the world and exclusive distributor of the Bellissima DMS Screening. With 5 production facilities on 4 continents, a strong portfolio of clients in over 80 countries and a high-performance continuous improvement culture, Apex’s value proposition is founded on developing solutions to satisfy the complex print challenges our customers face every day. Apex products are used in the Flexographic printing industry as well as the Offset, Industrial Coating and the Corrugated industry. As of June 5th, Carl Brock has been appointed as the Global Application Specialist for Bellissima screening, label and narrow web in the UK.

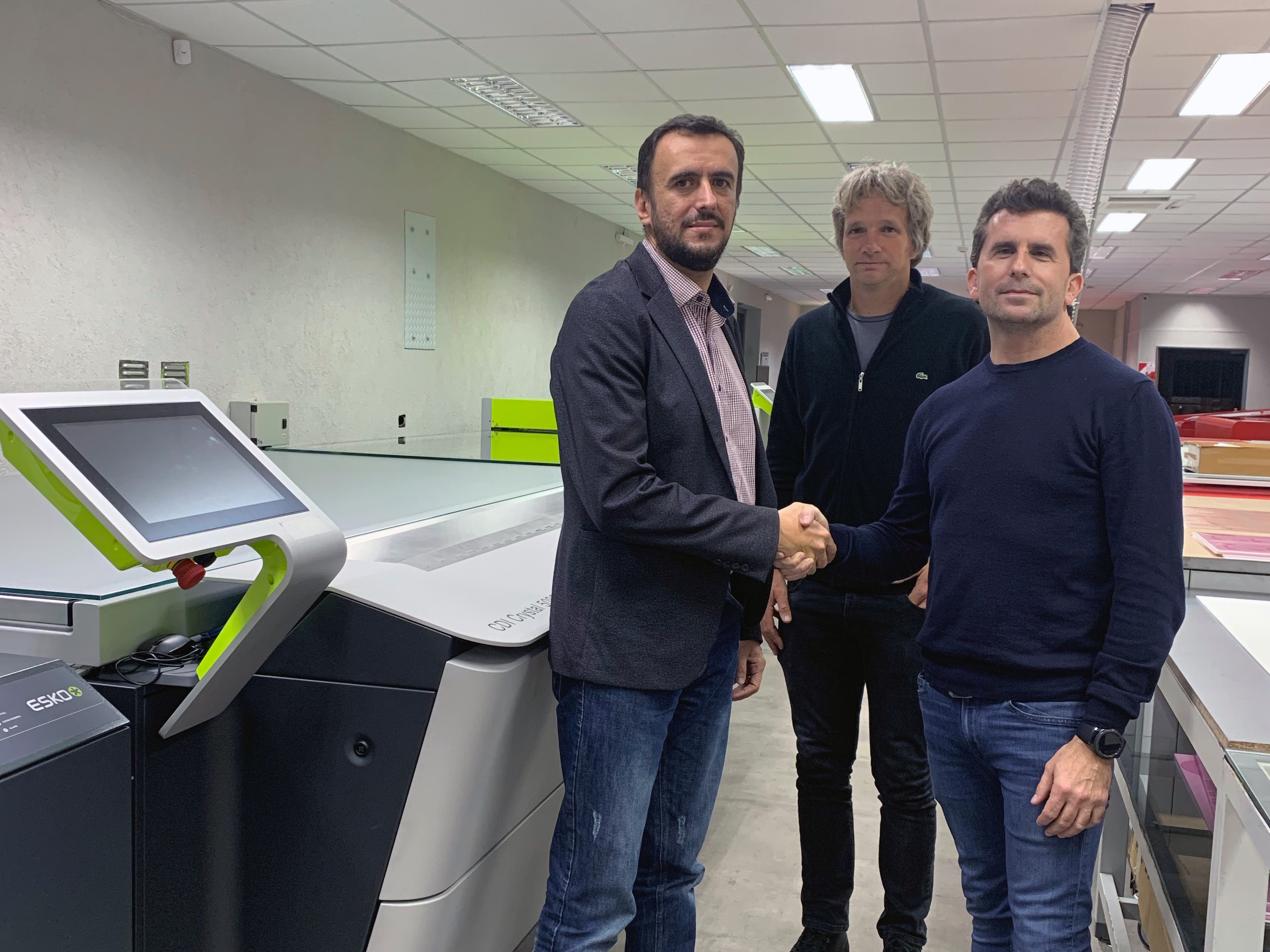

Read More >Fotograbados Lynch becomes first Bellissima DMS partner for South America

CAMBRIDGE, UNITED KINGDOM – Aniken Graphics, a joint venture between Hamillroad Software, a UK based prepress software company, and Apex International, a global leader of anilox and metering products, is proud to announce Fotograbados Lynch as its latest licensed Bellissima partner.

Read More >Beswick Machinery and Apex International, 5 years anniversary of Anilox and Print Solutions into South Africa

Beswick Machinery represents the world’s leading manufacturers of equipment for the packaging, converting and printing industries. The specialist team has over 180 years of experience between them and handles new equipment sales, spares ordering and processing, full installation, maintenance, training and process support.

Read More >