Accurate Anilox Roll Data = Better Print Quality, Less Waste, and More Uptime

Did you know that over 60% of printers we visit don’t have accurate data on the condition of their anilox rolls? If I had a dollar for every time we found one that had lost 30% or more of its original volume (BCM), I’d be cruising the Caribbean on a yacht by now. Operators are often shocked because they assume the roll’s volume is still what’s listed on the QC document. Spoiler alert: it’s not.

Did you know that over 60% of printers we visit don’t have accurate data on the condition of their anilox rolls? If I had a dollar for every time we found one that had lost 30% or more of its original volume (BCM), I’d be cruising the Caribbean on a yacht by now. Operators are often shocked because they assume the roll’s volume is still what’s listed on the QC document. Spoiler alert: it’s not.

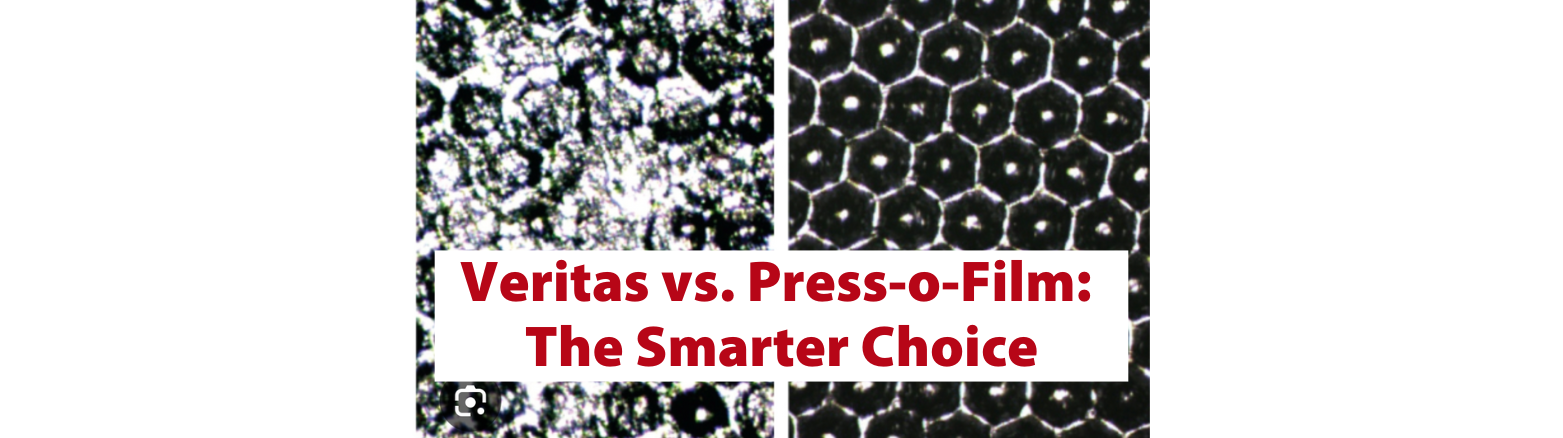

In this post, we’ll explore how outdated methods like Press-o-Films fall short and how Apex’s Veritas microscope audit gives you the precision, visibility, and confidence to reduce costs, eliminate waste, and improve print performance.

Why Regular Anilox Roll Audits Are Critical for Print Quality

.jpg?width=238&height=251&name=Anilox_Roll_Apex%20(1).jpg) Across our global network of customers, one thing is consistent: print issues often trace back to neglected anilox rolls. Whether you’re in North America, South America, Europe, or Asia, the story is the same.

Across our global network of customers, one thing is consistent: print issues often trace back to neglected anilox rolls. Whether you’re in North America, South America, Europe, or Asia, the story is the same.

Many daily press problems like dirty print, inconsistent colors, or excessive downtime are the result of worn, plugged, or damaged rolls that haven’t been properly monitored.

Routine anilox audits are essential for maintaining consistent, high-quality print results. They allow you to catch potential problems early, assess the effectiveness of your cleaning processes, and ensure your suppliers are meeting performance expectations.

Why Choose a Veritas Microscope for Your Anilox Audit?

Let’s be honest Press-o-Films are better than nothing, but it’s far from ideal. The results are inconsistent and heavily influenced by operator pressure, making volume measurements more of an educated guess than a reliable metric. Plus, it offers no visual or 3D insight into cell condition.

Let’s be honest Press-o-Films are better than nothing, but it’s far from ideal. The results are inconsistent and heavily influenced by operator pressure, making volume measurements more of an educated guess than a reliable metric. Plus, it offers no visual or 3D insight into cell condition.

The Veritas microscope changes that.

What makes Veritas better?

-

-

3D cell imaging for clear, detailed insight

-

Accurate, repeatable volume readings (not operator-dependent)

-

FTA Innovation Award winner for proven performance

-

Used globally at all Apex production sites, ensuring full transparency

-

When your sales rep uses the same tool as our engineers, you get traceability you can trust.

The Risks of Skipping Anilox Roll Inspections

Ignoring the condition of your anilox rolls doesn’t just affect print, it affects your bottom line. Here’s what we commonly see in plants that don’t audit:

Poor Print Quality: Plugged or worn rolls cause weak ink transfer, dirty print, and color variation.

Increased Waste: Incorrect BCM leads to wasted ink, substrate, plates, and time.

Frequent Downtime: You’ll spend more time troubleshooting and less time running jobs.

Shorter Roll Lifespan: Damage like score lines and corrosion go unnoticed—until it’s too late.

Higher Overall Costs: Long setups, rejected jobs, and press issues drive up expenses.

What to Expect from a Veritas Microscope Audit

When Apex performs an on-site Veritas audit, it delivers far more than just data. It’s a value-added service designed to produce immediate, measurable results.

Save Time, Money, and Materials

By knowing the exact condition of your anilox rolls before they affect print quality, you can prevent costly disruptions. Verified BCM data helps your team set up faster, improve ink transfer, and reduce job rejections, ultimately saving time, reducing material waste, and lowering production costs.

Gain Full Traceability

Gain Full Traceability

The Veritas audit also provides insight into roll health by identifying early signs of damage such as score lines or plugging. It allows you to track wear over time, validate the effectiveness of your cleaning processes, and make informed decisions about maintenance and replacement.

Build Operator Awareness

Each audit doubles as hands-on training for your pressroom staff. Operators learn best practices for roll handling and care, and the experience helps reinforce a preventative maintenance mindset that leads to better performance, longer roll life, and improved print results.

Schedule Your Free Veritas Audit Today

Apex offers Veritas audits free of charge for all our customers - better visibility, smarter decisions, and fewer headaches in your pressroom.

Ready to reduce downtime, boost print quality, extend the life of your anilox rolls, and give your team the training they need?

Schedule your free Veritas audit with Apex today »