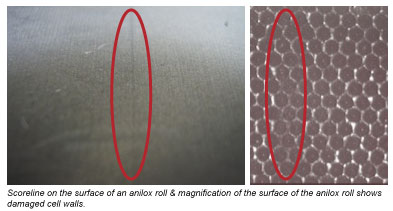

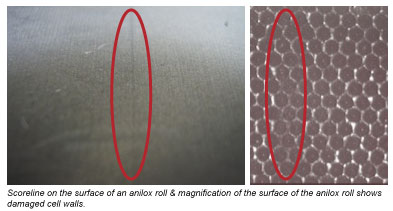

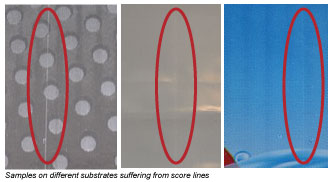

A score line in an anilox roll is a groove that has run directly through the engraved surface. The score shows a visible line in the printed or coated product and is irreversible. Once the surface is scored, the roll must be reconditioned or replaced. For these reasons, it is crucial to learn how to prevent scoring whenever possible. Below you will find an explanation on score lines, the different types and how to prevent them from occurring and keeping your print quality as high and consistent as possible.

3 types of score lines:

- Cosmetic or Preliminary

- Lightly Polished

- Severe or deeply gouged

What Causes Score Lines?

Over Impression

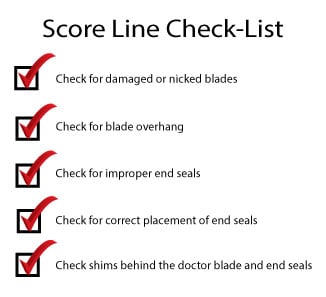

Over impression can cause premature wear to the doctor blade and roll. Long Blade tip slivers can easily cause score lines: these are formed when the blade bends back causing wear on the side rather than the tip. As the side of the blade wears through, the tip breaks away in the form of a long metal sliver. Normal shavings from blade wear from “kiss impression” will not damage a roll.

Doctor Blade Tip Material & Settings

Are you using the same blade for whites or metallic inks as you do for conventional ink? Using incorrect blade tip and material for type of ink can have disastrous results and hardened blades significantly increase the chance of scoring. The same can be said of replacing the blade on every anilox change. A blade “seats” to a specific LPI and is not meant to be used again. Blade forms to anilox and becomes a “Micro” saw. Finally, try resetting the doctor blade chamber after installing new blades. A worn blade is shorter than a new blade and if chamber does not reset, there will be excessive pressure.

Try a nickel coated anti-scoring blade. Nickel is softer than steel and ceramic, many converters use this very successfully as it is more forgiving and can cover potential misgivings in the metering process. It will also last longer because of coating; cleaner doctoring because blade is stronger; resist corrosion better because the blade has a barrier coating. And remember, always use higher quality blades. A low quality low cost blade can break down fast.

Helpful Tips:

- Coated blades are more forgiving than uncoated blades.

- The doctor blades should never extend past the ends of the seals, but should be flush and even with the bevels on the end seal.

- A coated blade will offer more “forgiveness” than an uncoated doctor blade and compensate for error

- Chattering blades vibrate and this action can act like a jack hammer to the ceramic and break cell walls

- If too soft, improper end seals will cause leakage and operator might adjust setting to compensate putting more pressure on anilox and stress on the blades. Do not set chamber to stop leaking.

- Correct placement of end seals allowing even contact with anilox and consistent transfer of the ink film to plat

- Shims break off or can become exposed to the anilox surface and cause scoring

- Ink resins can glue pigments, blade metal and other debris to the blade

Nick Harvey

Nick has more than 35 years’ experience in the flexo printing industry. Starting as a flexo print operator moving through the company structure , he later became the Production Manager of a large wide web flexible packaging company. Nick currently holds the role of Technical Director at Apex International, the world’s largest anilox manufacturer.