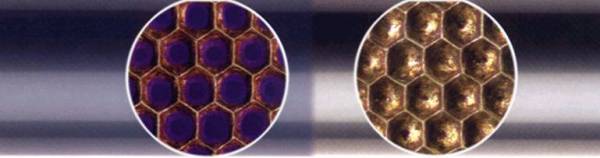

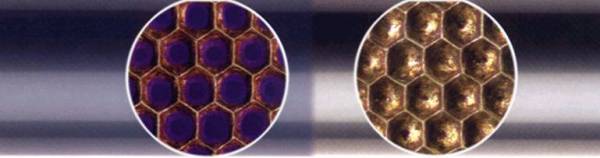

In order to maintain the life and performance standards of your anilox inventory, anilox rolls/sleeves must be cleaned immediately after a press run to remove the ink. If ink is allowed to dry, the build-up of deposits inside the cell decreases the amount of ‘fluid’ ink to be transferred onto a printing plate during subsequent runs. Because your volume transfer is not consistent, your print quality will become inconsistent too. By using a regular cleaning procedure, you can easily avoid this.

For daily cleaning of the anilox roll/sleeve:

- Clean water with a maximum possible Dh < 7°

- An alcohol based cleaning solvent

- A chemical cleaner (pH value between 6.5 – 10.5).

General notes:

- Use cleaning agents that are not harmful to the environment or your anilox rolls. All cleaning liquids must be in between 6.5 – 10.5 Ph. Note that when the value reaches < 5,5 the cleaning agent will become acidic and is dangerous for steel products. In cases where the value reaches > 11 Ph, aluminum can be affected.

- Do not use chlorine, ammonia or 100% acidic solutions for cleaning. These will attack the ceramic layer and cause corrosion.

- Always use a brush that is appropriate for the product you use. Specifically, a steel brush for ceramic rolls and a brass brush for chrome plated rolls.

Cleaning procedure for liquids:

- Apply the cleaning liquid of your choice onto the roll surface and allow it to soak.

- Clean the surface of the roll by using a brush (steel for ceramic, brass for chrome). Use a circular motion with maximum pressure. Be sure that the roll stays wet during this step.

- After cleaning, rinse the roll with clean hot water (max. 40 °C and Dh < 7°).

- Wipe it down (use a wiper or a lint free cloth).

- Check the roll and repeat the cleaning cycle as needed.

- Check that the roll/sleeve is dry, no drips should appear at the bottom side of the roll/sleeve. If drips appear, wipe them off.

- Let the rolls/sleeves dry (be sure to dry sleeves vertically)

- Store the roll/sleeve in a rack or in their original crate/package.

Additional information for Cleaning Anilox Sleeves:

- Do not submerge sleeves

- Avoid contact with petrolium based products

- After cleaning, store in vertical position on a heavy foam pad (TIR and concentricity!)

Doug Jones

Doug Jones is Vice President of Global Marketing at Apex International, the world’s largest manufacturer of anilox and meter products with 7 locations on 4 continents and sales offices covering over 80 countries. He holds a bachelors degree in Communications from Penn State and a Masters of Business Administration. He lives in Sewickely, Pennsylvania USA