When it comes to high-quality printing, the choice of anilox sleeves and coatings is critical for achieving superior results. Apex stands out in the industry not just as a manufacturer but as an innovator, offering products that address and solve key industry challenges. Here, we dive into the three core benefits that Apex delivers to its customers, with an analysis of the impact these benefits have on the printing industry.

1. Superior Construction: HD Anilox Sleeve Construction

Innovative In-House Manufacturing

Apex sets the bar high with its in-house anilox sleeve base manufacturing. This direct control over the production process allows Apex to address and mitigate common sleeve issues such as delamination, slipping, swelling, end ring detachment, and TIR (Total Indicator Runout) deterioration. By doing so, they not only ensure a higher standard of quality but also innovate in solving pervasive problems in the industry.

Enhanced Durability and Efficiency

The HD sleeves from Apex boast a design that is both watertight and submersible, tackling the usual  failures head-on. Their robust construction not only significantly reduces TIR failures but also, as a minimum, doubles the lifespan of the sleeves compared to industry norms. This longevity means increased rework potential and substantial cost savings for businesses, underlining Apex's commitment to operational efficiency and sustainability.

failures head-on. Their robust construction not only significantly reduces TIR failures but also, as a minimum, doubles the lifespan of the sleeves compared to industry norms. This longevity means increased rework potential and substantial cost savings for businesses, underlining Apex's commitment to operational efficiency and sustainability.

2. Cutting-edge Ceramic Coating

Minimizing Imperfections

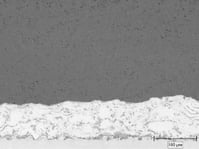

Apex's development of a highly compact ceramic coating represents a leap forward in anilox technology. Apex has managed to maximize the density and compactness of the ceramic coating more effectively  than ever before. The result is a surface that maintains its integrity and performance without the need of artificial sealants that are frequently used in the industry to mask ceramic porosity.

than ever before. The result is a surface that maintains its integrity and performance without the need of artificial sealants that are frequently used in the industry to mask ceramic porosity.

A key benefit of this pure ceramic coating is a more consistent foundation for the laser engraving process.

Long-lasting Performance

Customers have reported that the frequency of needing to clean the anilox increases as the anilox ages. This phenomenon may be attributed to the gradual deterioration of the artificial sealants, which are affected differently than the ceramic coating during cleaning. Over time, this can lead to irregular and rough inner cell or channel walls, providing a surface for ink or liquid to adhere to.

The pure ceramic coating developed by Apex does not require a porosity masking sealant and is designed to withstand repeated deep cleans without deterioration. This durability ensures consistent anilox performance, which in turn maintains ink consistency and reduces the overall maintenance workload in printing operations.

3. GTT 2.0 Technology

Revolutionizing Ink Management

Apex continues to push the boundaries with its GTT 2.0 technology. This proprietary engraving solution  significantly reduces ink aeration and lifting from cells post-doctoring, which in turn minimizes the need for plate cleaning. By ensuring the optimal ink density for high-quality printing results, GTT 2.0 technology represents a significant step forward in efficient ink management.

significantly reduces ink aeration and lifting from cells post-doctoring, which in turn minimizes the need for plate cleaning. By ensuring the optimal ink density for high-quality printing results, GTT 2.0 technology represents a significant step forward in efficient ink management.

Conclusion

Apex doesn't just supply products; it provides comprehensive solutions that address the core needs of the printing industry. Through superior construction, innovative ceramic coatings, and cutting-edge laser engraving technology, Apex ensures that its customers enjoy increased operational efficiency, cost savings, and unparalleled print quality. For businesses looking to stay ahead in the competitive printing industry, choosing Apex means investing in reliability, innovation, and excellence. Contact us today!