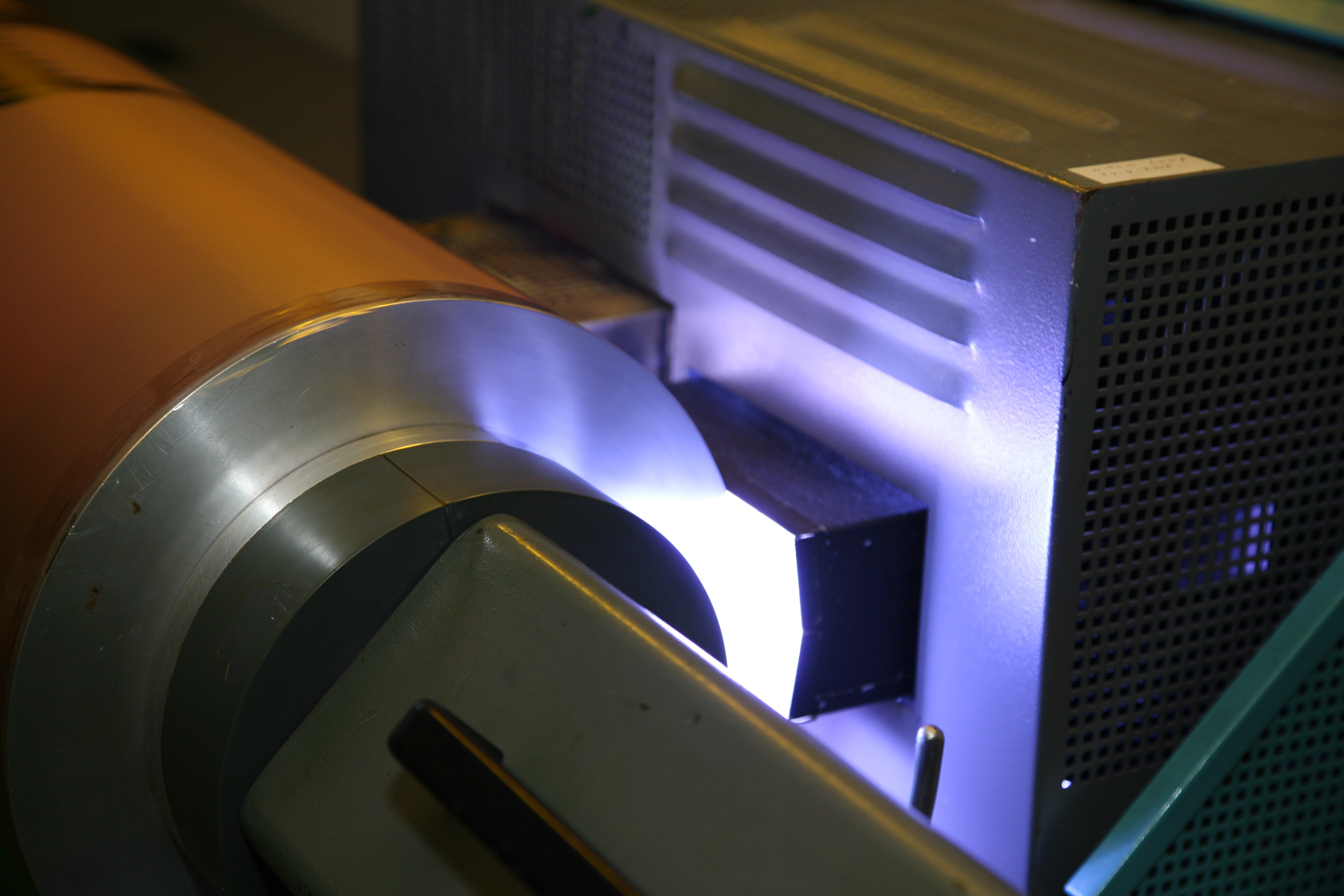

In recent times, the textile printing industry has witnessed significant advancements in rotary screen printing machines, particularly with the integration of Apex International rotary screen rolls. These machines are at the forefront of achieving top-quality fabric printing, streamlining production processes, and delivering dynamic designs. This article explores the latest trends and innovations in rotary screen printing machines, especially focusing on the contributions of Apex International's products to the textile sector.

Automation and Digitalization: Transforming Printing OperationsThe integration of automation and digitalization technologies has revolutionized rotary screen printing .jpg?width=287&height=191&name=studio%20(1).jpg) machines equipped with Apex International rotary screen rolls. These machines now offer enhanced precision and control, reducing the need for manual intervention. Automated rotary screen printers allow operators to adjust parameters such as speed, pressure, and color registration with ease, thereby minimizing human errors and ensuring consistent print quality. The adoption of sophisticated imaging software enables designers to create intricate patterns effortlessly.

machines equipped with Apex International rotary screen rolls. These machines now offer enhanced precision and control, reducing the need for manual intervention. Automated rotary screen printers allow operators to adjust parameters such as speed, pressure, and color registration with ease, thereby minimizing human errors and ensuring consistent print quality. The adoption of sophisticated imaging software enables designers to create intricate patterns effortlessly.

A notable trend in rotary screen printing machines is the emphasis on eco-friendly practices. With growing environmental concerns, textile manufacturers are adopting sustainable printing solutions. Machines fitted with rotary screen rolls can utilize eco-friendly dyes, pigments, and chemicals to minimize environmental impact. Moreover, manufacturers are adopting water-saving techniques and using eco-friendly fabrics, aligning with sustainable production principles.

Enhanced Speed and Productivity: Addressing Fast Fashion DemandsTo meet the fast-paced demands of the fashion industry, rotary screen printing machines have undergone enhancements in speed and productivity. The latest machines boast faster production rates, enabling textile manufacturers to meet tight deadlines and deliver large quantities of printed fabrics promptly. These advancements are crucial for businesses striving to excel in the fast-moving textile market.

Versatility and Durability: Adapting to Various Fabric Types Rotary screen printing machines have evolved to cater to a diverse array of fabric types, including delicate and stretchable textiles. Apex International has introduced innovative screen designs that enable printers to handle various fabrics seamlessly without compromising print quality. The enhanced durability of these screens ensures optimal ink transfer and consistent results, even after prolonged use, making rotary screen printers highly adaptable and resilient.

Rotary screen printing machines have evolved to cater to a diverse array of fabric types, including delicate and stretchable textiles. Apex International has introduced innovative screen designs that enable printers to handle various fabrics seamlessly without compromising print quality. The enhanced durability of these screens ensures optimal ink transfer and consistent results, even after prolonged use, making rotary screen printers highly adaptable and resilient.

In recent years, rotary screen printing machines have embraced cutting-edge printing techniques to meet evolving industry demands, such as three-dimensional and metallic effects on fabrics. Advanced rotary screen printers equipped with Apex International rotary screen rolls incorporate special screens and techniques to achieve raised textures, embossed designs, and metallic finishes. These innovative capabilities unlock new opportunities for designers and manufacturers to create visually captivating and distinctive fabrics.

Rotary screen printing machines, especially those equipped with Apex International rotary screen rolls, have undergone significant advancements and innovations, reshaping the textile industry landscape. The improvement in design detail ,accuracy and vibrancy takes the printed fabric to another level while ensuring heightened precision and quality. Eco-friendly initiatives drive sustainable printing practices, reducing environmental impact. Increased speed and productivity meet the escalating demands of the fashion industry, while versatility and durability enable the printing of various fabric types without compromising quality. Lastly, emerging techniques such as 3D and metallic effects are pushing the boundaries of fabric design. These advancements establish rotary screen printing machines as indispensable tools in the textile industry, ushering in new standards of creativity and excellence. Contact our team to discuss your goals and see the difference we can make in your rotary screen printing applications.

Rotary screen printing machines, especially those equipped with Apex International rotary screen rolls, have undergone significant advancements and innovations, reshaping the textile industry landscape. The improvement in design detail ,accuracy and vibrancy takes the printed fabric to another level while ensuring heightened precision and quality. Eco-friendly initiatives drive sustainable printing practices, reducing environmental impact. Increased speed and productivity meet the escalating demands of the fashion industry, while versatility and durability enable the printing of various fabric types without compromising quality. Lastly, emerging techniques such as 3D and metallic effects are pushing the boundaries of fabric design. These advancements establish rotary screen printing machines as indispensable tools in the textile industry, ushering in new standards of creativity and excellence. Contact our team to discuss your goals and see the difference we can make in your rotary screen printing applications.