When it comes to printing on corrugated packaging, achieving strong, opaque whites is a major challenge. White ink, especially on uncoated kraftliner or testliner, tends to struggle with coverage and often leaves rough, uneven edges. Traditional anilox rolls, while effective for many other colors, frequently fall short when it comes to producing crisp, solid whites. However, with Apex International’s GTT 2.0 technology, we’ve found a solution that not only strengthens white ink coverage but also delivers clean, sharp edges—transforming how we approach corrugated printing.

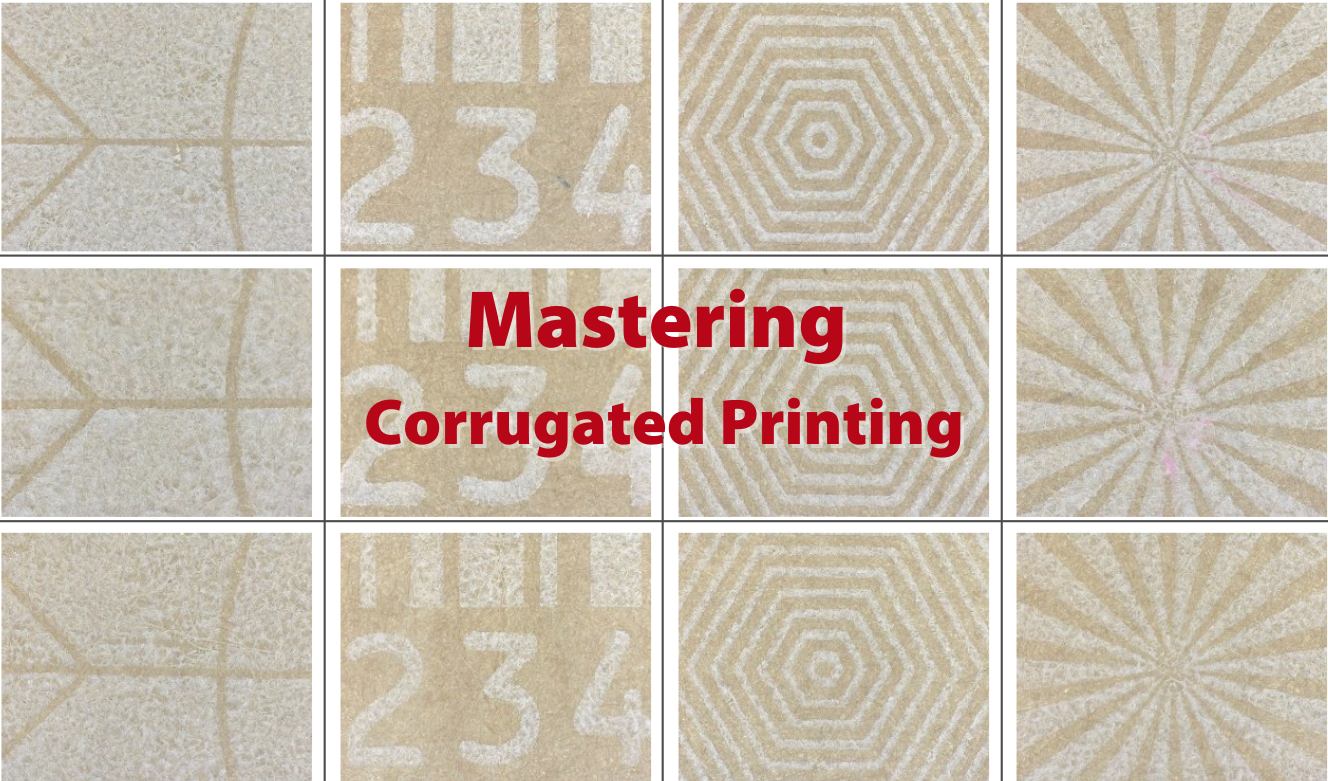

In this blog, we’ll explore the results of one of our recent trials where GTT 2.0 technology was put to the test on uncoated kraftliner and testliner. The outcome was remarkable, demonstrating how this technology offers superior control and precision, especially when it comes to the notoriously difficult task of printing white ink.

The Challenge: White Ink on Kraftliner

In flexographic and corrugated printing, white ink is often used as a base for underprinting other colors or as a key part of a design that needs to pop against the dark, natural tones of brown papers. However, achieving a bright, opaque white on this substrate can be challenging for several reasons:

- Ink Absorption: Testliner is porous and absorbs ink unevenly, leading to inconsistent opacity.

- Rough Surface Texture: The natural roughness of kraftliner can cause the ink to spread unevenly, resulting in jagged or unclear edges.

- Crushing Effect: Heavy white inks applied in large areas can cause the substrate to crush, creating unsightly blemishes and distorting the print.

With traditional anilox technologies, these problems often lead to subpar results—white prints that look faint, uneven, or messy, and designs that lack the clean, professional look brands expect.

GTT 2.0: A Solution for Stronger Whites and Cleaner Edges

The GTT 2.0 technology was designed to overcome the limitations of traditional anilox rolls by providing better ink flow control and more consistent ink laydown. In our trial, we put GTT 2.0 to the test by printing a large white design on uncoated brown kraftliner and testliner, one of the toughest substrates for white ink coverage. The goal was to achieve a solid, opaque white without the crushing effect or rough edges often seen with traditional printing methods.

The results were nothing short of impressive. GTT 2.0 enabled us to achieve:

- Stronger, more opaque whites: The white ink laid down evenly and consistently, creating a bright, opaque finish even on the rough surface of the kraftliner and testliner.

- Cleaner, sharper edges: The precision of GTT 2.0's ink flow prevented the typical spreading and feathering of ink, resulting in clean, defined edges around the white areas.

These benefits are due to the open-channel structure of GTT 2.0, which allows for smoother, more controlled ink transfer. Unlike traditional hexagonal anilox rolls, which often lead to ink pooling and uneven distribution, GTT 2.0 ensures that every drop of ink is placed exactly where it needs to be, with minimal waste or overapplication.

Case Study: Printing White on Brown Kraftliner

In this trial, we used E-Flute uncoated brown kraftliner, a substrate known for its rough, fibrous texture and high absorbency. We printed a solid white design using GTT 2.0 and compared the results with a traditional anilox roll. Here’s what we observed:

- Ink Opacity: With GTT 2.0, the white ink was bright and opaque, covering the brown paper without any patchiness. In contrast, the traditional anilox roll left a much weaker, semi-transparent white that did not achieve the desired contrast.

- Edge Clarity: One of the most remarkable differences was in the sharpness of the print. GTT 2.0 delivered crisp, clean edges, while the traditional anilox roll produced edges that were rough and uneven. This difference is crucial when it comes to intricate designs or text, where clean edges are necessary for a professional appearance.

- Ink Efficiency: GTT 2.0 also demonstrated better ink efficiency. The controlled ink flow meant that less ink was needed to achieve the desired opacity, reducing ink consumption and lowering costs without compromising quality.

Minimizing the Crushing Effect

Another critical issue when printing large areas of white on kraftliner is the potential for substrate crushing. When ink transfer from the anilox to the plate and then to the substrate is poor, press operators often try to fix the issue by increasing pressure between the anilox and the plate, as well as between the plate and the substrate. However, this approach can result in heavy flute-crushing, poor solid coverage, and weak print details.

GTT 2.0 addresses this problem by applying ink more evenly and efficiently, eliminating the need for excessive pressure on rolls and plates. As a result, our trial showed no evidence of substrate crushing, even in large, solid white areas. This is a significant advantage for printers, as it reduces the risk of wasted materials and costly reprints.

The Impact for Corrugated Printers

For corrugated printers, the ability to achieve strong whites with clean edges is a game-changer. White ink is a crucial element in many packaging designs, and poor white coverage can drastically reduce the visual impact of a product. With GTT 2.0, corrugated printers can now deliver high-quality white prints that meet the standards of even the most demanding brands.

For corrugated printers, the ability to achieve strong whites with clean edges is a game-changer. White ink is a crucial element in many packaging designs, and poor white coverage can drastically reduce the visual impact of a product. With GTT 2.0, corrugated printers can now deliver high-quality white prints that meet the standards of even the most demanding brands.

Some key benefits for corrugated printers include:

- Improved print quality: With GTT 2.0, you can achieve stronger whites and cleaner edges, giving your prints a more polished, professional appearance.

- Reduced ink waste: By using ink more efficiently, GTT 2.0 helps lower your ink consumption, saving costs and reducing waste.

- Minimized substrate damage: The more controlled ink application reduces the risk of crushing or damaging the substrate, which is especially important for delicate or lightweight corrugated materials.

Conclusion: GTT 2.0 Raises the Bar for White Ink Printing

Printing strong, opaque whites with clean edges has been a persistent challenge in the world of corrugated packaging, but with GTT 2.0 technology, this challenge can be overcome. The results from our trials demonstrate how GTT 2.0’s precise ink control enables brighter whites, sharper edges, and more efficient production on even the toughest substrates like uncoated kraftliner.

As more brands seek high-quality, eye-catching packaging, GTT 2.0 provides the solution that corrugated printers need to deliver superior results. Whether you're printing large blocks of white or intricate designs, GTT 2.0 ensures that your prints will stand out for their clarity, sharpness, and professionalism.

Stay tuned for more insights from our blog series as we continue to explore how GTT 2.0 is transforming the corrugated printing landscape.