In the world of corrugated printing, maintaining sharpness, clarity, and contrast is essential for delivering high-quality results. A common challenge that printers face is dot gain, where ink spreads beyond the intended area during printing, leading to:

Blurry images Loss of detail Reduced contrast

Blurry images Loss of detail Reduced contrast

This issue is particularly problematic when working with complex designs or fine details that demand precision.

With Apex International’s GTT 2.0 technology, corrugated printers now have a powerful solution that minimizes dot gain while enhancing overall contrast. In this blog, we’ll explore how GTT 2.0 improves print quality by delivering:

Cleaner dots Sharper details Better contrast

Even if you don’t print fine images or illustrations, this blog is still highly relevant—and here’s why:

Why GTT 2.0 Matters for Every Corrugated Printer

-

-

Sharper prints with minimal maintenance – GTT technology delivers cleaner, sharper dots while reducing the need for frequent plate cleaning.

-

Enhances clarity for all print elements – Not only does it improve high-resolution graphics, but it also ensures text, lines, and solid blocks appear crisper and more defined.

-

Boosts productivity and profitability – Less downtime, higher efficiency, and improved print quality directly impact your bottom line.

-

The Problem of Dot Gain in Corrugated Printing

Dot gain happens when ink spreads on the substrate, causing dots to print larger than intended. This leads to muddy images, blurred text, and reduced contrast—a challenge that is even greater when printing on porous and uneven surfaces like kraftliner and recycled paper.

Dot gain happens when ink spreads on the substrate, causing dots to print larger than intended. This leads to muddy images, blurred text, and reduced contrast—a challenge that is even greater when printing on porous and uneven surfaces like kraftliner and recycled paper.

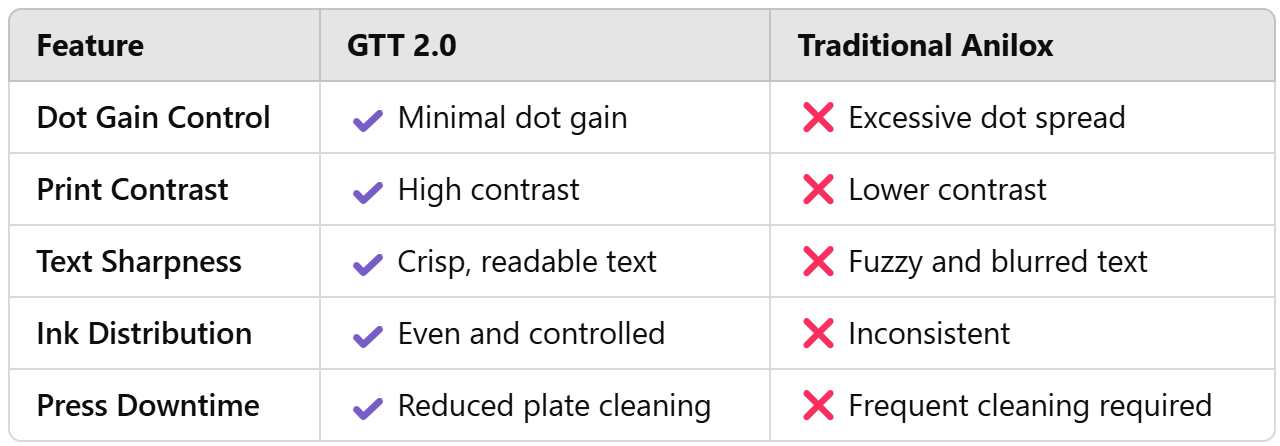

Issues with Traditional Anilox Rolls:

-

-

Inconsistent ink distribution

-

Fine details become less defined

-

Combination of solid and screen printing on one plate leads to reduced contrast

-

Prints look washed out and unprofessional

-

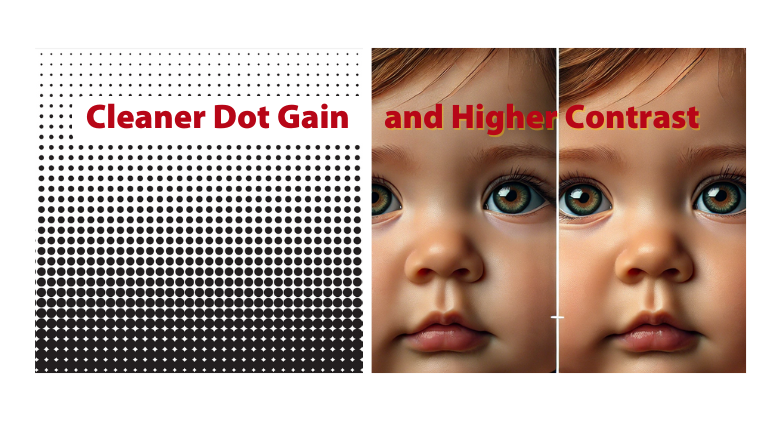

GTT 2.0: A Solution for Cleaner Dots and Higher Contrast

How GTT 2.0 Improves Print Quality

GTT 2.0 technology is engineered to provide precise ink control, solving dot gain and contrast challenges. Its open-channel structure ensures that ink is distributed evenly and efficiently across the substrate, significantly reducing dot gain.

GTT 2.0 technology is engineered to provide precise ink control, solving dot gain and contrast challenges. Its open-channel structure ensures that ink is distributed evenly and efficiently across the substrate, significantly reducing dot gain.

Key Benefits:

-

-

Dots remain sharp and well-defined

-

Ink distribution is more controlled

-

Higher contrast in printed designs

-

Reduced plate cleaning and press downtime

-

GTT 2.0 in Action: High-Contrast Printing on Uncoated Kraftliner

We recently conducted a trial on E-flute uncoated kraftliner, comparing GTT 2.0 with a traditional anilox engraving. The results were clear:

-

-

Sharper Dot Formation – GTT 2.0 significantly reduced dot gain, resulting in cleaner, more precise dots.

-

Higher Contrast – The open-channel structure of GTT 2.0 allowed for more consistent ink transfer, leading to bolder dark areas and clearer light areas.

-

Sharp Text and Fine Details – Small text and intricate patterns remained crisp and readable, unlike traditional engravings which caused text to appear fuzzy and less legible.

-

Comparison Results: GTT 2.0 vs. Traditional Anilox

The Benefits for Corrugated Printers

By switching to GTT 2.0, corrugated printers can achieve:

By switching to GTT 2.0, corrugated printers can achieve:

-

-

Sharper details and better contrast

-

Reduced dot gain for cleaner images

-

Improved print consistency across different substrates

-

Fewer reprints and less waste

-

Optimized combination printing of solid and screen elements on one plate

-

Conclusion: Elevating Corrugated Printing with GTT 2.0

The ability to control dot gain and maintain high contrast is essential for producing professional-grade corrugated prints. GTT 2.0 technology is a game-changer, offering superior control over ink distribution while eliminating common issues like dot gain and blurring.

With GTT 2.0, printers can achieve: ✅ Sharper images ✅ Cleaner text ✅ Stronger contrast ✅ Less downtime and higher productivity

With GTT 2.0, printers can achieve: ✅ Sharper images ✅ Cleaner text ✅ Stronger contrast ✅ Less downtime and higher productivity

For printers looking to improve print quality, reduce downtime, and boost efficiency, GTT 2.0 is the ultimate solution.

Stay tuned for more insights from our blog series as we continue to explore how GTT 2.0 is transforming the corrugated printing industry!