Detecting Abrasive Ink: The Simple Tribology Test

At Apex International, we believe better print quality starts with better process control and that includes knowing exactly how your ink is impacting your press. While most printers focus on pigment load, color strength, and drying times, few stop to consider one silent press killer: abrasive ink.

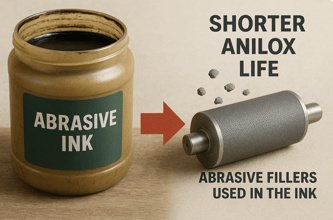

Not all inks are created equal. Some formulations include fillers that can significantly increase wear on anilox rolls, metering components, and even pumps. These hidden abrasives quietly degrade performance, shorten equipment life, and inflate maintenance costs. Thankfully, there’s a fast, affordable way to detect this issue before it causes damage: the Tribology Test.

What Is the Tribology Test?

Tribology is the study of friction, wear, and lubrication. In the printing industry, it’s a powerful diagnostic tool that reveals whether your ink is contributing to excessive wear or premature component failure.

This simple yet effective Tribology Test was developed in collaboration with TCB BVBA, a respected European consultancy specializing in the analysis and evaluation of inks, coatings, and printing systems. With decades of experience in tribological testing, TCB has helped bring scientific clarity to real-world printing challenges, making it easier for printers to identify and address ink-related wear before damage occurs. Using just a high-gloss aluminum plate, a soft cloth, and your ink, you can quickly determine whether abrasive fillers are present. The results are visual and immediate:

- No ink – just rubbing: Minimal polish, little wear

- Good ink (no fillers): Smooth lubrication, low surface impact

- Abrasive ink (with fillers): Clear scratching or polishing, visual signs of surface degradation

These results help pinpoint when ink (not press components) is the real issue, something both printers and ink suppliers have long struggled to verify.

Why Fillers Are Used—and Why They Matter

So why do ink suppliers include fillers in the first place? Often, it's a matter of cost. In industries like corrugated, fillers are commonly used in extenders to reduce pigment load and lower formulation costs. However, these short-term savings can lead to long-term equipment wear and production losses. Alternatives exist—such as less abrasive extender technologies—but they often come at a higher price point.

Protecting Your Anilox Investment

At Apex, we manufacture the world’s most consistent and durable anilox rolls, but even the best technology can’t fully withstand abrasive inks. That’s why it’s critical to identify ink-related issues early. Our ceramic  technology offers several clear advantages that can significantly reduce wear—even in challenging environments:

technology offers several clear advantages that can significantly reduce wear—even in challenging environments:

- No Sealant in Ceramic: Our ceramic is not sealed, maintaining a more robust and wear-resistant surface.

- More Compact Coating: Denser ceramic structure means better durability and cleanability.

- GTT Technology: Unlike traditional 60-degree angle engravings (like H60), GTT’s channel structure runs in the machine direction, reducing friction points that typically accelerate wear.

While no ceramic can eliminate the risk of abrasion completely, Apex’s technology offers superior resistance compared to conventional options—protecting your investment and improving long-term performance.

Apex’s Commitment to Performance and Process Control

This simple Tribology Test aligns with our mission at Apex: to maximize performance and minimize waste. We’re here to support printers in achieving:

- Longer lasting anilox and glue sets

- Reduced downtime and maintenance

- Higher-quality, more consistent print results

- More sustainable and cost-effective production

Whether you’re using GTT 2.0, standard engravings, or OEM-specified rolls, knowing what’s in your ink is just as critical as what’s in your roll.

Take Control—Before the Damage Is Done

Abrasive ink is invisible to the eye but devastating over time. With the Tribology Test, you gain proof, insight, and the power to take action.

Want to know if your ink is doing more harm than good?

Let Apex help you evaluate and extend the life of your anilox technology.

Contact your Apex representative or visit apexinternational.com to learn more.