Apex International is proud to share the results of a unique print initiative: a cross-company collaboration that produced a fully finished demonstration piece designed to highlight what modern coating technology can achieve when paired with Apex GTT technology.

Apex International is proud to share the results of a unique print initiative: a cross-company collaboration that produced a fully finished demonstration piece designed to highlight what modern coating technology can achieve when paired with Apex GTT technology.

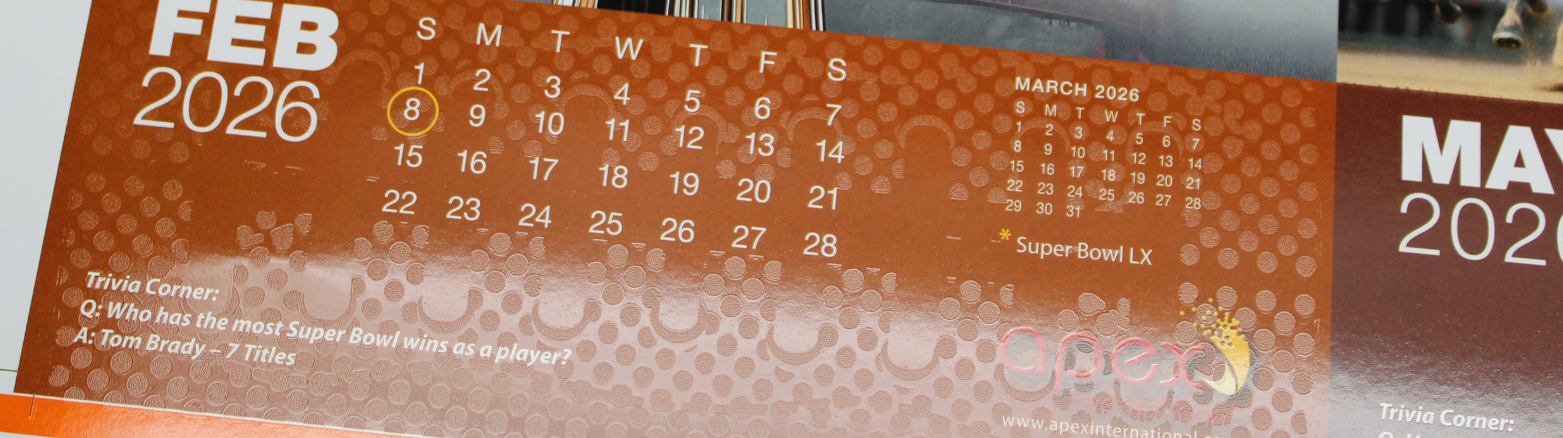

Although delivered in the form of a 2026 desktop calendar, the true purpose of the project goes far beyond dates or design. It's about demonstrating real, measurable differences in coating performance, print consistency, and cross-border collaboration within the Apex network.

A Project Created to Prove What Is Possible

The idea was simple: Create a real-world commercial print sample that any printer, anywhere in the world could relate to, examine, evaluate, and learn from.

Instead of relying on small test sheets or isolated coating samples, Apex developed a fully functional product that:

Instead of relying on small test sheets or isolated coating samples, Apex developed a fully functional product that:

- runs on actual production equipment

- uses customer-grade substrates

- incorporates multiple coating techniques

- mirrors the same challenges printers face every day

The result is a demonstration piece that shows (rather than tells) the performance advantages of consistent anilox technology.

Collaboration Across Teams and Partners

The project brought together multiple companies, combining their expertise into one unified effort:

- Apex North America led the initiative and coordinated print development.

- Lake County Press (USA) executed printing and coating with precision.

- Stahl supplied materials, technical insight, and support.

This partnership showcases how Apex collaborates across regions and with customers to solve real production challenges and push innovation forward.

Real Coating Effects Under Real Production Conditions

To ensure authenticity, every coating was applied on a flexographic coating unit configured to replicate conditions found in facilities around the world.

To ensure authenticity, every coating was applied on a flexographic coating unit configured to replicate conditions found in facilities around the world.

The demonstration piece features:

- soft-touch coatings

- high-gloss finishes

- reticulation and texture effects

- specialty combinations achieved through precise GTT anilox selection

There were no lab shortcuts, just real coatings, real substrates, and real press conditions.

Demonstrating the GTT Difference

This project provides a clear, hands-on example of why GTT anilox technology is trusted by printers globally. During the production of the demonstration piece, Lake County Press operators shared direct, measurable feedback that highlights the impact of predictable coating volume, optimized gloss levels, and consistent laydown performance.

This project provides a clear, hands-on example of why GTT anilox technology is trusted by printers globally. During the production of the demonstration piece, Lake County Press operators shared direct, measurable feedback that highlights the impact of predictable coating volume, optimized gloss levels, and consistent laydown performance.

To illustrate the real-world impact, here are two standout observations from the pressroom team:

"I gained 15 gloss points using your roll."

– Ben, Press OperatorThis gain reflects a common advantage of GTT’s controlled cell geometry. Its ability to deliver smoother, more uniform coating laydown contributes directly to higher and more repeatable gloss values—an essential factor in packaging, publishing, and premium print work.

– Brian Popp, Pressroom Manager

Soft-touch coatings are highly sensitive to coating weight, surface uniformity, and anilox condition. Brian’s feedback reinforces a key benefit of GTT technology: a smoother, more controlled deposition that enhances tactile performance and creates a premium, velvet-like finish.

Why These Results Matter

The testimonials reinforce what printers consistently experience with GTT anilox technology:

The testimonials reinforce what printers consistently experience with GTT anilox technology:

- more consistent coating volume delivery

- optimized flexographic and offset coating performance

- higher gloss and improved tactile finishes

- 10–20% coating savings in many applications

- better predictability across long production runs

The demonstration piece allows industry professionals to see, touch, and compare these improvements firsthand.

A Global Message From Apex

More than a print sample, this project reflects Apex’s core values:

- collaboration

- innovation

- data-driven improvement

- customer-centered problem solving

- unwavering commitment to raising print and coating standards worldwide

Whether a printer is working in corrugated, labels, flexible packaging, or offset coating applications, the project is a reminder that consistent anilox technology is the foundation for consistent coating results.

A Demonstration Piece With Purpose

While the final product is a calendar, the real purpose is much broader: To give the print community a hands-on example of what can be achieved when advanced coating technology, skilled partners, and reliable anilox performance come together.

While the final product is a calendar, the real purpose is much broader: To give the print community a hands-on example of what can be achieved when advanced coating technology, skilled partners, and reliable anilox performance come together.

It is not just a sample. It is a proof-of-concept, demonstrating Apex’s commitment to innovating alongside the printing industry and helping customers achieve more predictable, more efficient, and more visually impressive results.

Ready to See What GTT Can Do for Your Coating Applications?

Discover how consistent anilox technology can transform your production. Contact our technical team or request a consultation today.