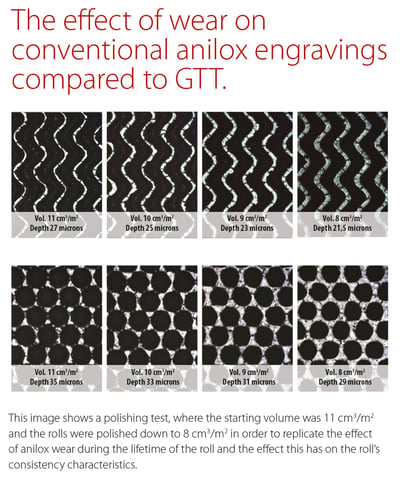

Both Apex and its customers need to measure aniloxes - but for different reasons! Control and consistency are the foundation for process standardization, ECG printing and improved productivity in flexographic printing. The anilox surface – where ink meets plate – has always been the foundation for achieving high print quality on a repeatable basis “ideally” without constant process adjustments. Apex focused on this challenge and reinvented the basics of ink-to-plate transfer by creating the Patented GTT engraving. This advancement has resulted in a far more consistent anilox which is proven, both in print production at customers and internally with the microscopic measurement control possible from both Troika and MD control systems. These two systems validate that Apex aniloxes are produced globally with the highest level of accuracy.

For printers the need to monitor the anilox on a monthly basis is critical to ensure the consistency of printing in particular ECG without continually chasing “their tail“ with process adjustments. It is now up to printers to take full advantage of this control and boost the results on their presses.

In response to the industry’s growing need to reduce down time and increase productivity without compromising quality standards, Apex developed a new way to get the flow of ink exactly right. It successfully brought GTT version 1 to market over ten years ago. Nick Harvey (Technical Director at Apex International) explains: “During the conceptual development of GTT, Apex investigated all possible engraving structures and created GTT which is a fusion of all the positives that can be achieved in part by other engravings.” “we do this by combining three revolutionary technical innovations:

1 - Low-porosity hybrid ceramic surface layer

1 - Low-porosity hybrid ceramic surface layer

2 - The use of a constant beam laser

3 - An Open Slalom Ink Channel geometry engraving

With the above combination we have been able to reinvent ink transfer and greatly improve its consistency.” Additionally, GTT enables Apex to facilitate the increased industry demand to manufacture every GTT profile perfectly to give exactly the same print performance from roll to roll, plant to plant , month after month.”

Measure and monitor

Apex has put in place an additional global calibrated system in order to constantly monitor the quality and consistency of the anilox rolls it manufactures and supplies – both GTT and all cell based engravings.

Apex recently invested in 10 Troika AniCAM 3D microscopes which are running alongside the existing equipment from Microdynamics at Apex. This duel calibrated quality control process has further improved the accuracy across the global production. Jon Jordan (Sales Director at Troika) explains how Troika’s AniCAM microscopes benefit both Apex and printers in the field: “A printer wants confirmation that his roll is clean, or clogged, or maybe worn – and he wants proof of this off line. This has to do with the cleaning and maintenance regime and wear, and we can help to measure and monitor this. On the other hand, Apex, as an anilox manufacturer, needs to measure and control screen and volume because this has to be the same to customers now and in 6 months; it needs to be standardized and the same for all its different plants."

Different use and application

It is important to understand the very different demands and environments in the use and application of the same type of microscop es, emphasizes Harvey: “Taking good measurements with a 3D microscope depends on many factors, such as the light settings, the lens and the magnifying range, calibration and of course the stability of the environment (for example the vibration like a press running or a forklift passing nearby will cause irregular readings). Different systems and different settings will deliver different results which makes comparing measurements impossible – especially when we are calculating fractions of microns. Remember that a human hair has a thickness between 30 and 50 microns whereas a 3cm3/m2 volume anilox engraving will have approximately 9 microns in depth.”

es, emphasizes Harvey: “Taking good measurements with a 3D microscope depends on many factors, such as the light settings, the lens and the magnifying range, calibration and of course the stability of the environment (for example the vibration like a press running or a forklift passing nearby will cause irregular readings). Different systems and different settings will deliver different results which makes comparing measurements impossible – especially when we are calculating fractions of microns. Remember that a human hair has a thickness between 30 and 50 microns whereas a 3cm3/m2 volume anilox engraving will have approximately 9 microns in depth.”

Apex has completely standardised and optimised its measurement methods and environment, to ensure the accuracy and consistency of the volume and screen measurements. Harvey continues: “Printers will find it almost impossible to be able to mimic these conditions. This means that the Apex “laboratory“ method of anilox measurement and the measurements achieved at customers on the same anilox roll will always risk to show variations between them.

Apex has completely standardised and optimised its measurement methods and environment, to ensure the accuracy and consistency of the volume and screen measurements. Harvey continues: “Printers will find it almost impossible to be able to mimic these conditions. This means that the Apex “laboratory“ method of anilox measurement and the measurements achieved at customers on the same anilox roll will always risk to show variations between them.

However, printers are perfectly capable of monitoring their anilox rolls for wear and tear during their lifetime with these microscopes – and this too will have a positive effect on both productivity and output print quality. Apex strongly advocates the use of a calibration anilox roll for printers to have as a reference roll for all subsequent measurements this will help to compensate for the different environment variations that will occur.”

For further information on QC Reference rolls for in house anilox measurement control please refer to us. We will bring you in contact with one of our technical experts that speaks your language.

This is part 2 in a series of 3 short articles on anilox measurements and accuracy, read the first article (The Need for Accurate Anilox measurement) here. The 3rd article with the experiences of a UK-based label printing group will be published next week!