*Originally published in FLEXO Magazine's June 2019 issue

There was a time not too long ago when flexo corrugated and folding carton printing consisted of adding a blue or black logo with text to a plain cardboard box as a means to transport products safely and identify "this way up" or "fragile."

That’s not the case anymore.

Like many other technologies over the past decade, corrugated and folding carton printing have evolved to become much more advanced, incorporating high-definition imagery, a wider range of colors, and more intricate shapes and designs.

You may have seen evidence of this in your most recent trip to the grocery store. Pop-up displays and product packaging have grown to be more detailed, enticing and even interactive, as many brands have begun to utilize nearly invisible QR codes and digital watermarks.

The surge in online shopping and the need to give a better consumer purchasing experience are pushing brands to rethink the old concept of a box existing purely to transport a product safely, into a true consumer experience. Consider that when consumers visit a store, they can be enticed to buy a product with point-of-sale promotions, two-for-one offers or end-of-aisle pop-up promotions.

When a consumer doesn’t visit a store and buys online, those key points of sale are lost. When a consumer purchases online, all products can be made to look equally enticing.

Therefore, the brands and retailers now have only three points of sale:

- Marketing digital, magazines and TV

- Online shopping

- The box in which the product is delivered

Brands see their packaging as a final opportunity to advertise and deliver their message to consumers, both after the purchase is made and as a trigger to drive them to purchase before a decision is made. Therefore, these brands expect precision and clarity in the printed products that represent them.

Where there is change in consumer habits, there is also an opportunity! Packaging can evolve and be at the forefront of this changing purchasing environment.

Ever Efficient

Keeping up with all the advancements in the industry, as well as customer demands, can be difficult, especially when the average production length of corrugated jobs is getting shorter and shorter. This puts extra pressure on the print departments to reduce job changeover times and improve press efficiencies.

To help corrugated and folding carton printers to reduce costs and deliver maximum quality to the variety of boards and liners they produce today, anilox manufacturers have developed new screening patterns and technologies that enable better ink laydown on recycled board, improve graphic resolution, reduce skip feeding (allowing better ink laydown from one pass) and the rise in high-definition/fixed palette graphics, aimed at folding carton and corrugated high graphic designs POP.

The challenge has been taking anilox screen rulings from 200 lpi to 500 lpi for corrugated and 700 lpi to 1,200 lpi for folding carton and having these anilox rolls work in conjunction with the printing plate with screen rulings between 65 lpi and 150 lpi. At the same time, we have to ensure the anilox rolls are effective and efficient with ink release.

|

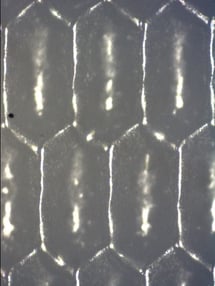

A LongCell Engraving |

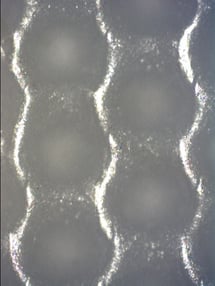

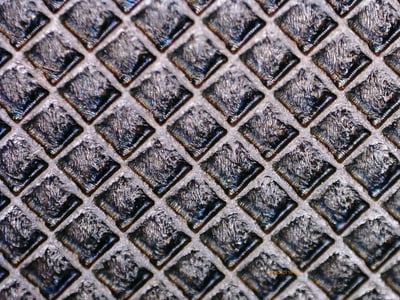

Standard anilox roll cell with a 30-degree engraving Standard anilox roll cell with a 30-degree engraving |

Standard anilox roll cell with a 60-degree engraving Standard anilox roll cell with a 60-degree engraving |

Most anilox cell technologies today are known by brand names which are linked to a manufacturer, but in principle these engravings are simply 30 degrees, 45 degrees or 60 degrees. These conventional-type engravings are all manufactured on a single or multi-hit pulsed laser. They have served the corrugated and folding carton industries well since the dawn of time.

New Developments

Six years ago really saw the start of new laser advancements in multi-hit 500-w. laser engravers, allowing anilox manufacturers to really start to look at what cell shapes they can offer that will provide much better ink laydown. With the advancements, the risk is that now manufacturers can engrave extreme depths that create higher volume but will also create a high-maintenance roll that requires excessive cleaning.

The benefit of these “LongCell” -types of engravings is that they do produce better ink solids.

The disadvantages of this engraving are:

- Ink usage is increased

- Dot gain is increased, which reduces image quality

- Moirè risk is increased, due to the extended and wider angle created within the cells

One clear point to understand is that a LongCell engraving has two lpi, unlike a 60-degree engraving. This means that from left to right, an engraving can be 600 lpi, but from top to bottom, the engraving will be around 300 lpi.

Additionally, the tolerances on conventional anilox engravings, as in industry standard rolls, are around +/-10 percent between the same spec roll. This could mean in a 3-color press, a printer could believe it has three identical rolls, but they could all have varying volumes/performances. For example:

- Target = 330 lpi with a target volume of 5.2 bcm

- Deck 1 = 4.68 bcm

- Deck 2 = 5.2 bcm

- Deck 3 = 5.72 bcm

These rolls would be classed as in tolerance of +/-10 percent; however, from an ink laydown and color laydown perspective, the differences could be dramatic.

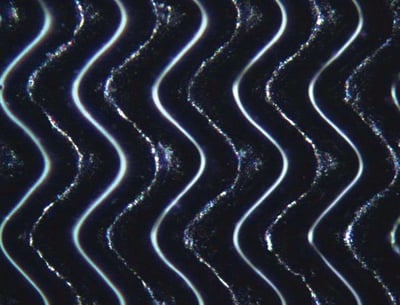

In 2013, Apex North America launched a new innovation called GTT (Genetic Transfer Technology) to the North American corrugated and folding carton market. GTT has an open slalom ink channel geometry, which comes from a constant laser beam, which will deliver smooth and precise walls to the slalom profile.

Unlike engravings with six walls around the cell profile and tolerances of +/-10 percent, GTT has two continuous walls that enable production to deliver tolerances of zero to +5 percent. Also, GTT is not specified by screen and bcm (360 lpi at 6.5 bcm); it’s specified by a size (XL, L, M, S and XS), meaning an inventory of fewer anilox rolls with a wider range of flexibility no matter what the print substrate is. In corrugated, the standard has become the L specification, which allows a printer to maintain heavy solids but clean screen of up to 85 lpi on the plate.

GTT Engraving

GTT Engraving

Allowing ink to flow freely with no rotational backflow lifting results in improved print characteristic for corrugated and folding carton. Printers report:

- Stronger solids with less pinholing

- Sharper and finer screen print

- Less dot gain

- Reduction in skip feeding

- Better control of Pantone colors

Closed Loop Control

As we move deeper into 2019, fixed palette printing is becoming more of a topic, especially for folding carton, and the role of the anilox is key in this process to ensure a consistent volume of ink is applied to allow the fixed colors to produce the correct Pantone colors.

Achieving color consistency is probably the most difficult component of transitioning to a fixed palette process. Fixed palette is only possible with precise control: control over variables, control over ink flow and so on. It proves difficult, sometimes impossible. But always remember: The anilox is a key foundation for the print.

Here's where you can read the original story from FLEXO magazine.

David McBeth

David McBeth currently serves as the Vice President of Sales for Apex North America. He has worked within the flexographic print sector for more than 30 years and has served as a board member of the EFTA in Europe. He holds an MBA in business psychology and economics.