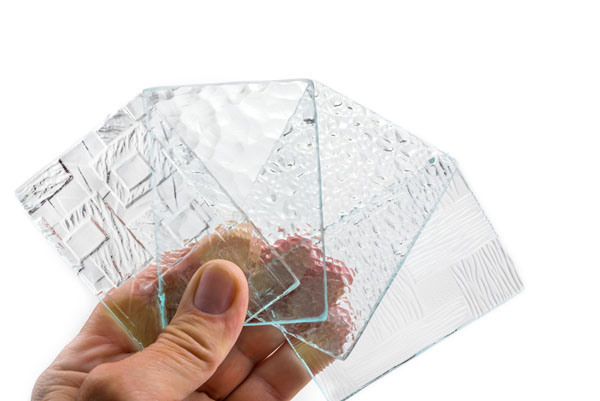

Industrial embossing is a technique used by manufacturers to enhance the aesthetic and tactile qualities of a wide range of applications including home and auto products, non-woven or paper substrates, plastics, metal or even glass. The most common method for rotary embossing typically uses two rollers made of steel or rubber, which are manufactured as mated pairs and fit together to mechanically press the pattern or design into the substrate surface. Thermal embossing is another method that utilizes heated rollers to impart the unique visual or tactile finishes. Both rotary and thermal embossing processes demand a high level of engraving accuracy with extremely tight tolerance windows. Read our Embossing 101 blog on “Types of Embossing” for more information.

Apex Embossing is a global manufacturer of high-quality embossing rollers, offering decades of experience in design and application. As a trusted supplier, we know the important factors for quality embossing rollers. Let’s take a look…

Key Embossing Roller Characteristics

While the exact roller selection will be dependent on several factors, including the embossing method and the material to be embossed, there are some key characteristics that will be verified across your high-quality embossing rolls.

.jpg?width=167&height=134&name=stand%208%20(1).jpg) Pattern Precision. Embossing rollers must be engineered with precise, often intricate, designs that are responsible for transferring specific textures and patterns onto materials, from fine details to larger, bold designs. Without precise pattern engravings, the rollers may transfer incomplete or uneven textures, leading to visible inconsistencies and poor-quality impressions on the material.

Pattern Precision. Embossing rollers must be engineered with precise, often intricate, designs that are responsible for transferring specific textures and patterns onto materials, from fine details to larger, bold designs. Without precise pattern engravings, the rollers may transfer incomplete or uneven textures, leading to visible inconsistencies and poor-quality impressions on the material.

Material Durability. Typically made from hardened steel, chrome-plated steel, or high-quality alloys, embossing rollers should be built to endure high-pressure applications and frequent use, with a focus on longevity. Rollers made of subpar materials can wear out quickly, requiring reconditioning more often and reducing profitability.

Surface Hardness. Quality embossing rollers are often heat-treated or hardened with advanced metallurgy to withstand abrasion and corrosion, resist wear, and ensure a uniform embossing effect across extended production runs. Rollers that lack proper hardness may not emboss the surface as desired and could wear more easily, or worse, stop production due to breaks in the pattern.

Engraving Quality. The engraved surface on embossing rollers can be created via mechanical engraving, chemical etching, or laser engraving, and must be engraved precisely according to the intricacies and durability required. Poor engravings will impact the sharpness and clarity of the embossed designs, making final patterns appear blurry or faded, reducing the visual impact, especially for intricate designs.

Engraving Quality. The engraved surface on embossing rollers can be created via mechanical engraving, chemical etching, or laser engraving, and must be engraved precisely according to the intricacies and durability required. Poor engravings will impact the sharpness and clarity of the embossed designs, making final patterns appear blurry or faded, reducing the visual impact, especially for intricate designs.

Alignment and Repeat Accuracy. For Industrial embossing rollers with repeating patterns, like wallpaper and flooring, the engravings must be highly precise, ensuring consistent pattern alignment across long runs and on wide materials so transitions are seamless. Misaligned or poorly designed engravings could cause final patterns to appear offset.

Thermal Stability. Embossing rollers in thermal applications, such as glass embossing, must tolerate high  temperatures without warping, allowing them to work with materials that may require heat to soften for embossing, like plastic films, glass, or certain metals. If embossing rollers are not properly prepared for thermal application they may warp and wear, causing uneven impressions and potential damage to the substrate and/or equipment.

temperatures without warping, allowing them to work with materials that may require heat to soften for embossing, like plastic films, glass, or certain metals. If embossing rollers are not properly prepared for thermal application they may warp and wear, causing uneven impressions and potential damage to the substrate and/or equipment.

Customization and Application-Specific Design. These rollers can be customized to meet specific industry requirements, such as anti-slip textures for flooring, brand logos on packaging, or decorative finishes on textiles. Without an experienced partner, you may not have the best roller customized to achieve your surface and/or desired effect.

There are many factors to producing high quality, high performing embossing rollers and therefore, it’s incredibly important to select an embossing roller partner with the experience and technology to guarantee the precise, durable, and repeatable textures required by various end-use applications.

Apex Quality Embossing Rollers

Apex Embossing is a reputable supplier of embossing rollers, with over 150 years of experience and global manufacturing capabilities to offer exceptional quality and service. We understand the level of accuracy -1.jpg?width=250&height=167&name=studio%20(1)-1.jpg) necessary to bring your embossing applications to life and have invested in the technology to get the job done. Whether your design includes micro dots, dots, lines, angles, smooth or custom engravings, our team can help reproduce and proof your designs using on-site proofing equipment. We also assist with pattern testing and design updates, along with a final quality check to perfect your rolls for production.

necessary to bring your embossing applications to life and have invested in the technology to get the job done. Whether your design includes micro dots, dots, lines, angles, smooth or custom engravings, our team can help reproduce and proof your designs using on-site proofing equipment. We also assist with pattern testing and design updates, along with a final quality check to perfect your rolls for production.

Apex Embossing utilizes the latest laser, etching and knurling techniques for ultimate manufacturing quality, along with a finishing process that includes chrome plating for a smooth finish and lasting roll longevity. When you partner with Apex Embossing, you partner with a global manufacturer dedicated to roll quality and support. For embossing rollers with all the key characteristics for excellence, choose Apex. Contact us today for a quote!