Van Dam Machine’s new FDoR® technology allows for flexographic printing directly onto rigid packaging

A new technology designed by Van Dam Machine will now compete with label and IML decoration techniques. This new FDoR® technology enables images and designs to be printed with photographic quality. Such quality is achieved at a substantially lower price level and a greatly-improved environmental footprint.

FDoR is a flexographic printing method whereby the required process colors are first collected on the blanket wet-on-wet as a complete picture before transferring the ink onto the rigid product.

Van Dam Machine chose to partner with Apex International due to its reputation for innovation and its state-of-the-art anilox technology.

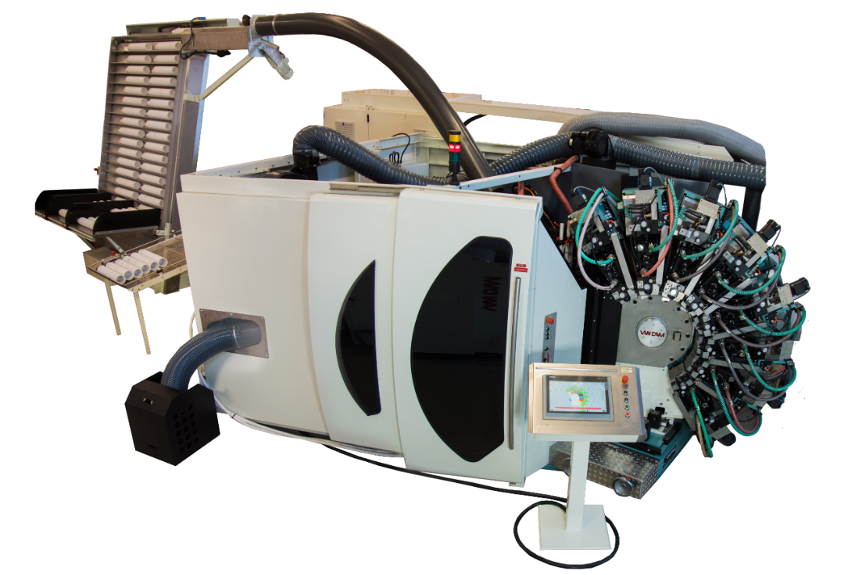

Van Dam manufactures two variants of flexo presses for the cup market:

- FDoR machines – based on cylindrical plate cylinders and aniloxes. This press has seen improvement in quality and consistency improvement when printing with Apex International’s GTT2.0 engraving technology — which is now Van Dam’s approved engraving for use with FDoR machines.

- FlexoCon technology encompasses Van Dam Machine’s conical roller design.

Knowing that conical products are the most common rigid packaging products available, Van Dam Machine designed the FlexoCon, which also makes use of FDoR technology. FlexoCon allows for distortion-free printing on conical products.

Printing conically – and therefore distortion-free – has two advantages. One, it will result in an absolute copy of a label print on conical shapes. And two, conical printing allows for printing on paper and molded fiber products, because the surface is printed without friction. For transferring the ink, the color heads need to be conical, including the anilox rolls.

Printing conically – and therefore distortion-free – has two advantages. One, it will result in an absolute copy of a label print on conical shapes. And two, conical printing allows for printing on paper and molded fiber products, because the surface is printed without friction. For transferring the ink, the color heads need to be conical, including the anilox rolls.

Apex International’s GTT2.0 technology is an open channel structure anilox engraving for cylindrical aniloxes. Apex and Van Dam have developed together a new engraving structure that uses the G(TT open-channel technology and fuse it with a unique algorithm to produce a technology breakthrough in anilox structure that enables the production of conical aniloxes. This newly designed engraving technology is called CRX(PATENT PENDING).

A conical anilox can only hold an engraving pattern which is not based on axial barriers. Axial barriers will compromise the conical function of the roller. A fusion of engravings was required to create a structure in a radial direction on the anilox surface. Apex and Van Dam developed this engraving to hold and transfer inks, to limit leakage, and optimize the ink layer.

To accommodate for the conical shape, the engraving design of the anilox rolls are compensated to ensure that the engraving pattern remains continuous. In addition, the engraving pattern may not be isolated – meaning the engraving technique requires to be a unique interlinked design. Utilizing the patented GTT2.0 laser engraving technology, air is allowed to flow out of the channels prior to entry into the doctor chamber for ink replenishment, and thus entrapment of air is reduced. Such defined control of the flow of liquid and air is essential to deliver a consistent ink transfer.

The challenge was to create an engraving that provided a consistent ink flow on:

- A conical shape; and

- A press that has each inking unit set at a different angle to vertical.

The engraving has to compensate for the different unit angle and the conical shape allowing the Ink to flow consistently across the anilox surface – as in a maze. Too open a channel will result in ink leakage and inconsistent color from top to bottom of the cup, while a closed engraving will result in other print issues including shade variation at different speeds.

The engraving pattern is laser engraved using a fusion of GTT2.0 technology along with a uniquely designed algorithm to ensure the repeatability and quality of ink transfer

The new CRX engraving technology is available in seven types (XXS , XS , S , M , L , XL , XXL) with each size increasing in volume based on a fixed optimum geometry.

Nick Harvey

Nick has more than 35 years’ experience in the flexo printing industry. Starting as a flexo print operator moving through the company structure , he later became the Production Manager of a large wide web flexible packaging company. Nick currently holds the role of Technical Director at Apex International, the world’s largest anilox manufacturer.