In today’s flexographic printing environments, anilox sleeves play a critical role in print quality, consistency, and efficiency. Manufactured to tight tolerances and engineered for precise ink transfer, they are also a significant investment. While most operations focus heavily on cleaning and inspection, one area is often overlooked: protection during handling, storage, and movement.

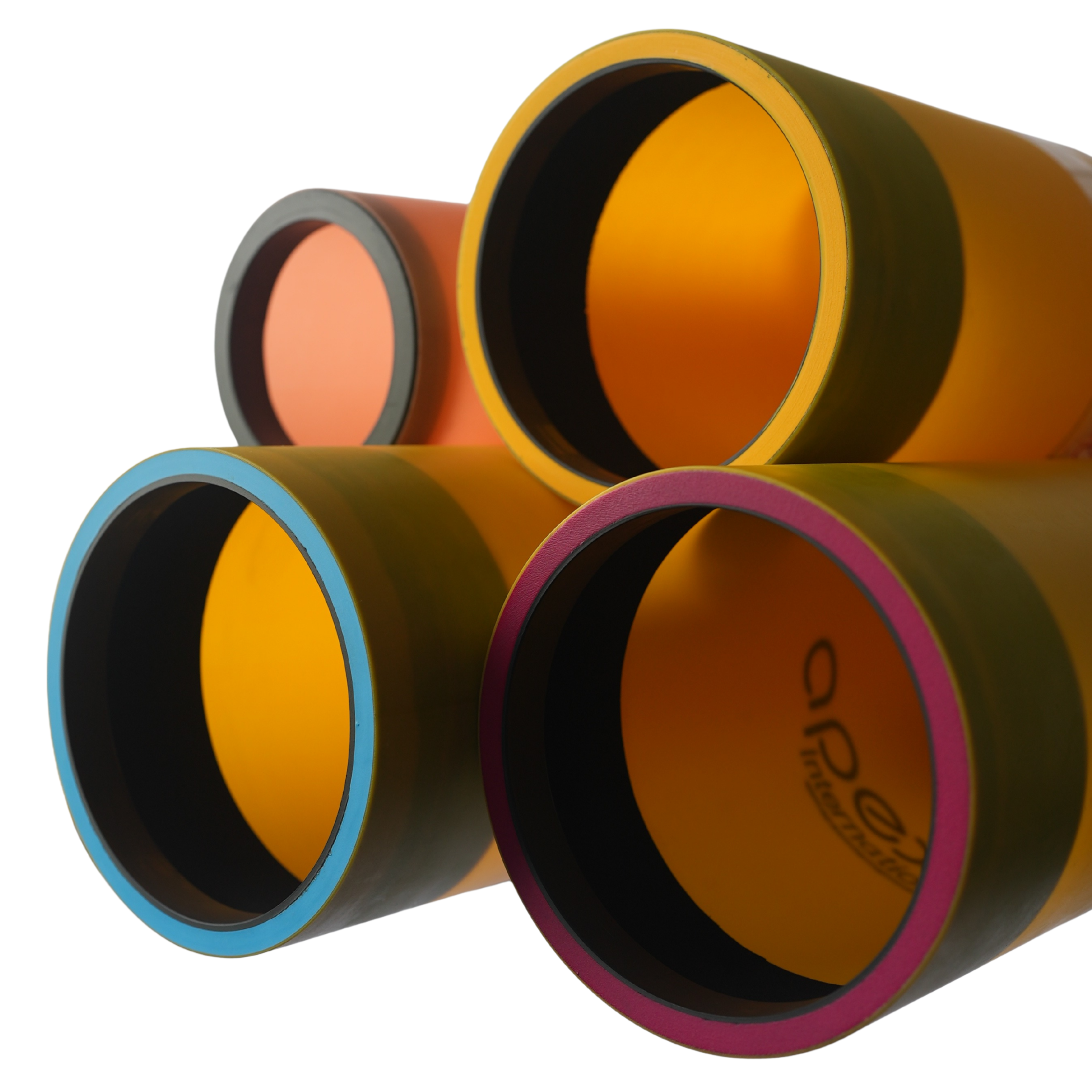

Anilox Armor sleeve covers are designed to fill that gap, not as a cosmetic accessory, but as a practical, protective solution that helps preserve sleeve condition and performance between press runs.

Where Anilox Damage Really Happens

Despite their importance, anilox sleeves are most vulnerable when they are off press. Changeovers, staging, transport, and temporary storage all introduce opportunities for damage, often unintentionally and often unnoticed until print quality is affected.

Common risks include:

- Accidental impacts during transport or installation

- Scratches from contact with carts, racks, or surrounding equipment

- Surface damage caused by debris or improper storage

- Dust and contamination settling on exposed ceramic surfaces

- Minor knocks that compromise surface integrity over time

Even small defects can disrupt ink transfer and shorten sleeve service life.

Purpose-Built Protection for Real Production Environments

Apex’s Anilox Armor sleeve covers are engineered specifically to protect sleeves during the moments they are most exposed. By creating a durable barrier around the ceramic surface, the covers help reduce the risk of impact damage, abrasion, and contamination during everyday handling.

They are intended for use during:

- Sleeve transport within the plant

- Short- and long-term storage

- Off-press staging between jobs

- Press installation

Design features include:

- Durable construction with air-cushion protection suitable for daily handling

- Materials that protect without damaging ceramic surfaces

- A secure, consistent fit during transport and storage

- Straightforward installation and removal

The goal is simple: protect sleeve surfaces without slowing down production or adding unnecessary complexity.

Designed to Integrate into Existing Workflows

In high-throughput production environments, protective solutions must be easy to use. If protection is inconvenient, it will be skipped. Apex’s Anilox Armor sleeve covers are designed with usability in mind, allowing operators to install and remove them quickly while maintaining a secure fit during movement.

This balance of protection and practicality encourages consistent use across shifts and departments.

Supporting Consistent Print Quality and Asset Life

Supporting Consistent Print Quality and Asset Life

Protecting an anilox sleeve is not only about avoiding major damage. Repeated minor impacts and exposure to contaminants can gradually degrade performance, even if the damage is not immediately visible.

By reducing cumulative wear, sleeve covers help:

By reducing cumulative wear, sleeve covers help:

- Maintain surface integrity

- Support consistent ink transfer

- Reduce unplanned repairs or re-engraving

- Extend overall sleeve service life

For many operations, this translates into more predictable performance, fewer disruptions, and better long-term return on investment.

A Practical Extension of Anilox Care

Anilox care programs typically focus on cleaning, inspection, and measurement. Protection during handling and storage is a natural extension of those efforts. Sleeve covers help safeguard anilox surfaces between cleaning cycles and press runs, closing a critical gap in asset protection.

Rather than reacting to damage after it occurs, sleeve covers support a preventative approach that aligns with modern maintenance and reliability strategies.

Built with the Apex Performance Mindset

Apex’s Anilox Armor sleeve covers are developed with the same performance-driven approach applied to anilox manufacturing itself. Designed specifically for flexographic printing operations, they are built to withstand real production conditions while delivering reliable, repeatable protection.

Apex’s Anilox Armor sleeve covers are developed with the same performance-driven approach applied to anilox manufacturing itself. Designed specifically for flexographic printing operations, they are built to withstand real production conditions while delivering reliable, repeatable protection.

By reducing avoidable damage and preserving surface integrity, sleeve covers help printers protect precision assets, maintain consistent print quality, and control long-term costs.

Protecting anilox sleeves is not about adding another step. It is about protecting the performance you already depend on.

To learn more about Anilox Armor sleeve covers or to discuss how they can support your anilox care strategy, contact the Apex team today.